Product Liability: Tire Defect Cases; Product Liability and Design Defect Cases in Georgia

Posted by Wetherington Law Firm | Articles

- Articles

- Artificial Intelligence

- Car Accidents

- Class Action Lawsuit

- Comparative Negligence

- Crime Victim

- Defective Vehicles

- Disability

- Kratom Death and Injury

- Legal Marketing

- Motor Vehicle Accidents

- News/Media

- Other

- Pedestrian Accidents

- Personal Injury

- Results

- Sexual Assault

- Truck Accidents

- Uber

- Wrongful Death

Categories

Practice Tips From Matt Wetherington on Screening Products Liability Cases in Georgia

A young man is a passenger in a vehicle traveling on the highway. He is properly wearing a seatbelt, the vehicle is traveling within the speed limit, and everything about the trip has been unremarkable. Suddenly, the vehicle makes a loud noise and the driver loses control. The vehicle begins to rollover, ejecting the young man onto the roadway. The driver walks away from the wreck, but the young man becomes a quadriplegic. The wreck report cites the driver of the vehicle for “failure to maintain lane” and indicates that the passenger was not wearing his seatbelt. An investigation will reveal that the vehicle experienced a tread separation and the seatbelt unlatched during the wreck. These defects, not the driver, are primarily responsible for the wreck. But, the family does not know this information and contacts an attorney to sue the “negligent” driver.

In the late 1800s, families faced a similar tragedy. Children in Chicago were becoming sick and dying. Like the family above, parents did not know the true cause of their children’s deaths. Many blamed readily observable causes, such as an infection. In reality, Chicago’s meatpacking district had institutionalized manufacturing processes that poisoned the public with lethal meat:

There would be meat stored in great piles in rooms; and the water from leaky roofs would drip over it, and thousands of rats would race about on it. […] These rats were nuisances, and the packers would put poisoned bread out for them; they would die, and then rats, bread, and meat would go into the hoppers together. This is no fairy story and no joke […] cartload after cartload of it would be taken up and dumped into the hoppers with fresh meat, and sent out to the public’s breakfast.[1]

When this practice was made public, the law did not allow the family of a poisoned person to hold a meat packing company responsible for its actions due to a lack of privity. Despite this legal hurdle, public outrage against poisoned food ushered in a wave of legal claims against product manufacturers, including mass-produced vehicles introduced to broader markets. After a number of setbacks, Justice Cardozo opened the courthouse doors for these families by recognizing that where a product is “reasonably certain to place life and limb in peril when negligently made . . . then, irrespective of contract, the manufacturer of this thing of danger is under a duty to make it carefully.” MacPherson v. Buick Motor Co., 111 N.E. 1050, 217 N.Y. 382 (1916). Thus, the modern era of products liability was born. In Georgia, this principle is codified in O.C.G.A. 51-1-11(b):

The manufacturer of any personal property sold as new property directly or through a dealer or any other person shall be liable in tort, irrespective of privity, to any natural person who may use, consume, or reasonably be affected by the property and who suffers injury to his person or property because the property when sold by the manufacturer was not merchantable and reasonably suited to the use intended, and its condition when sold is the proximate cause of the injury sustained.

Unfortunately, even with the legal structure necessary to seek justice, most victims do not recognize when a wreck is caused by, or injuries exacerbated by, a defective vehicle. Based on a basic police report and a generic description of the wreck by the victims, it can also be difficult for even a skilled attorney to recognize a potential products liability claim. Nonetheless, highway wrecks involving dangerous and defective vehicles continue to account for a significant portion of the more than 30,000 lives lost each year in wrecks.[2] Although it is impossible to fully explore the many ways a vehicle may be defective, this paper is written as an introductory guide to some of the most common auto defects and emerging trends that will become common without industry intervention. It also outlines some of the steps that you can take to investigate the existence and strength of a potential product liability claim.

Tire and Automobile Defects

These defect claims typically cover the vehicle itself and all connected components.

Tire Defect Claims

Tire failures come in many forms, from simple flat tires to catastrophic tread-separation events. Regardless of the severity of the tire failure, defectively designed and manufactured tires are the underlying cause of many of the failures. Many other failures are caused by poor maintenance or servicing.

Despite the tire industry’s lackadaisical approach to informing the public of the common dangers associated with tires, they are the most important stability control systems on a vehicle. Tires transfer braking and driving forces from the vehicle to the pavement. As a result, it is imperative that tire makers design and manufacture tires that are able to withstand the strains and speeds of modern vehicles. Tire manufacturers have made extensive changes to the way tires are designed, manufactured, and sold to consumers since the first pneumatic tire was invented in 1845. In many ways, these changes have been positive. Modern tires last longer, offer superior fuel efficiency, and provide for a more comfortable ride. However, improvements in the long-term durability of tires have also given rise to problems involving the breakdown of rubber components over time and the inability of tires to withstand reasonably foreseeable workloads and vehicle speeds. When compounded by longstanding design and manufacturing defects, it is no surprise that tire failures are on the rise throughout the United States.

Tire defect claims arise in a number of ways, including design defects, manufacturing defects, negligent service and repairs by retailers, and a general failure of the entire tire industry to adequately warn of known hazards, such as tire aging.

In any case where a defective tire is suspected, it is important to get an expert involved to advise of potential claims.

Rollovers

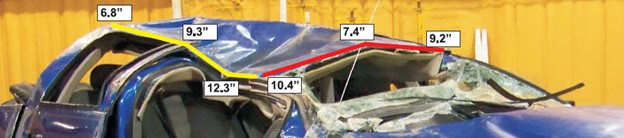

A rollover raises the possibility of two categories of defects: failure to design a car to avoid a rollover altogether, and a failure to design a vehicle to protect the occupant space in the event of a rollover. The first category, often referred to as a “stability” defect, involves cars with a higher center of gravity that make them susceptible to rollover. Electronic stability control can often prevent rollovers in foreseeable wrecks, but it was not a standard feature until 2012.

The second category is a crashworthiness theory: if a car does rollover, it should be designed with sufficient roof strength to protect its occupants. Otherwise, a crushed roof in a rollover wreck can lead to a loss of occupant space and can cause serious injury including spinal injuries and death. Roof strength is one of several components of rollover safety. The safety restraints should keep the occupants belted in position and the doors and windows should keep them contained in the vehicle. Safety canopies (rollover airbags) and side curtain airbags can also provide protection in a rollover.

Sudden Unintended Acceleration

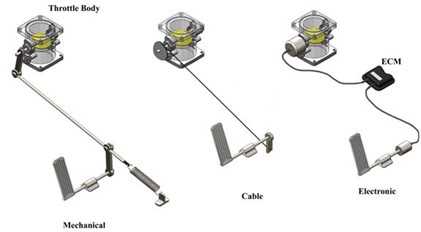

Before the proliferation of electronic controls in cars, there was a physical connection between the gas pedal and the throttle. This design ensured that the position of the gas pedal corresponded to the opening of the throttle. In today’s vehicles, however, electronic signals travel from the pedal to a central processing unit, and the onboard computer tells the throttle how much to open in response:

When this system malfunctions, it can result in sudden unintended acceleration (SUA).

Auto manufacturers have long claimed that SUA is the result of human error. However, research into the problem has shown that defects in the electronics that control acceleration can cause SUA. And where there is a traditional throttle cable, a claim may exist where the cable was repaired, but when repaired, became kinked and ultimately caused the vehicle to continue to accelerate even though the driver tried to stop the vehicle. In SUA cases, physical evidence, including driver injuries, the placement of the driver’s foot, witness marks on the driver’s shoes, location of the floor mat, witness testimony about evidence of braking, and damage to the gas and/or brake pedals may provide important physical evidence that the driver attempted to brake but the vehicle did not respond.

Occupant Containment

If an occupant was ejected from the vehicle in a wreck, there may be a crashworthiness claim. Vehicle manufacturers have a duty to protect occupants from being ejected in foreseeable crashes. There are a variety of measures that can prevent ejection. Obviously, properly designed and functioning seatbelts are a must. Side airbags can also effectively prevent ejection. Where an occupant is totally or partially ejected from a shattered window, there may also be a “glazing” claim. Glazed, or laminated, glass allows the window to shatter without breaking out in a wreck. Federal regulations require this technology be used on windshields, but manufacturers often do not use this available safety technology on side windows or sunroofs. In addition, where an occupant is ejected through a vehicle door during a wreck sequence there may a defect in the door latching mechanism. Doors must be designed to stay closed in a foreseeable wreck.

Seatbelt Failures

There are a wide variety of potential seatbelt defects. If a passenger is found without a seatbelt after a wreck, do not assume that he or she was not wearing the seatbelt. Design defects can cause a seatbelt to come unlatched during a wreck sequence.

Alternatively, seatbelt retractors have been known to “spool out,” allowing excess slack in the belt during the wreck. Anytime a seatbelt is found with excess slack in it after a wreck or if the belt appears not to have held the occupant in place, there may be a spooling issue. Check for striation marks, lock-up marks, witness marks made from the plaintiff hitting parts of the vehicle, and discuss the plaintiff’s injuries with a biomechanical expert to determine whether his injuries are the type that would be caused by a spool out.

The two-point “lap” belts (as opposed to three-point belts with a shoulder strap), common in older-model cars, can cause serious injury, including paralysis and tearing of the intestines. Manufacturers have known about this risk for years but nonetheless continued to use the dangerous two-point belt design. Passive restraints, such as shoulder belts that automatically engage when the door is closed, can also cause fatal injuries.

Post-Collision Fuel-Fed Fires

Cars should not catch on fire in wrecks that the occupants can survive. Post-collision fuel-fed fires occur when the fuel system is not adequately protected from the most likely impact areas. The fuel tank should be located inside the frame rails and away from these likely areas of impact, the tank should be protected from other fuel system components, and there should be features that reduce or eliminate fuel spillage and ignition when the system is compromised. If a wreck involves any kind of fire, the potential product claim should be very carefully considered.

Seat and Seatback Failures

Seats should be sufficiently rigid to remain upright in most collisions. Seatback failures occur when the seatback collapses in a collision, sending the occupant backward into the seat behind him or ejecting him out of the vehicle entirely. This can cause paraplegia, quadriplegia, or death to the occupant of the failed seat or the person seated behind him. As a practical matter, it can also cause the driver to lose control of the vehicle. Severe injuries and a collapsed seatback signal that there may be a claim for a defectively designed seat.

Airbag Deployment

Airbags cases can come in a variety of forms. The most obvious cases are impacts in which the airbag failed to deploy. Note, however, that airbags are not designed to deploy in all wrecks. For example, rear impacts will not cause frontal airbags to deploy. And some airbags are only designed to deploy in side impacts or rollovers.

Airbags can also inadvertently deploy where no collision occurred. In these cases, the airbag may cause injury, or it may cause the driver to lose control of the vehicle causing the wreck. Airbags themselves can also cause unnecessary injury if they are designed to deploy so aggressively that they cause injury to the passenger they are intended to protect.

Everything Else

The most important thing to look for to recognize a products liability case is something out of the ordinary. If it seems like a vehicle’s design simply should not have killed or injured the victim—then it probably shouldn’t have. One example is power window switches that rock back and forth to roll the window up and down. This design allows children to be injured or killed if they lean out the window and inadvertently put their hand on the switch, rolling the window up and strangling themselves. Federal regulations have been enacted to require designs that protect against this, but manufacturers have a continuing duty to warn consumers of the risk of rocker switches still in circulation.[3] In addition, some of the newer model switches appear “safe” but in fact contain the same defect as the traditional rocker switch.

Today’s “smart keys”—systems with key fobs and on/off buttons—have created a human factors defect. Consumers often accidentally leave their cars running by failing to push the “off” switch when they exit the vehicle. Even though neither the driver nor the key fob remain in the car, the car will continue to idle until it runs out of gas. When a driver makes this mistake after parking in his garage, it can lead to carbon monoxide poisoning and death. Most manufacturers do not protect against this hazard by warning consumers of the risk or designing the vehicle to shut off after a period of inactivity.

Injuries caused by rollaway cars may also raise the possibility of a products claim. When a car shifts out of park it can rollaway, causing injury or death to people trying to stop it. This sometimes happens when a child in a parked car accidentally shifts the car into gear. Manufacturers are now required to safeguard against this foreseeable risk with designs that require the brake be applied before the gear can be shifted. But for many years, some manufacturers chose not to use this readily available technology.

General Investigation Principles

Once a defect is suspected, it is critical to follow best practices in the investigation and preservation of the vehicle. Failure to do so can subject the attorney to discipline.

Preserve Everything

Obtain and preserve the subject vehicle or product in addition to all other physical evidence, even the contents of the vehicle as soon as possible. Information and evidence can be lost with every passing day. If the vehicle is not in your client’s possession, then you will have to send spoliation letters. In many cases, it is best to purchase the vehicle so that it can be stored in a climate-controlled facility.

Perform a Thorough Examination

Examine and document the scene of the wreck as soon as possible. Request all public records, including 911 calls, first responder and law enforcement records, traffic or security camera tapes, etc. Talk to all witnesses, find out what they saw, and determine if they have any pictures or video. Consider whether to get affidavits from witnesses regarding critical facts.

In a products case, the mechanism of injury is often a key issue. Therefore, obtain all medical records, including x-rays and other tests. If the wreck involves a death, obtain the death certificate, ensure an autopsy is performed, and obtain the medical examiner’s report and photographs. Document “witness marks” inside the vehicle for evidence of where and how the occupants impacted the vehicle. Then, as discussed below, discuss the evidence with a biomechanical expert to determine the mechanism of injury.

Evidence from a vehicle’s “blackbox” or electronic data recorder (EDR) must be handled with great care. Before anything is done to the vehicle, make sure you have a highly qualified expert in the field perform a forensic download. A misstep could result in the loss of important evidence.

Run the vehicle’s VIN number through services like Carfax, Rigdig, and/or MVSCUSA to determine its service, wreck, and ownership history. Depending on the defect, this may be important and relevant information.

Involve an Expert Early

Engage an expert as soon as practicable to receive guidance in the direction and scope of an investigation. There is nothing short of a mountain of empirical and anecdotal evidence supporting that early engagement of an expert is important, yet a majority of litigants wait until after a complaint is filed and/or discovery is almost closed to hire an expert.[4] A well qualified expert who truly knows the field can help you analyze the potential strengths and weaknesses in the case and identify categories of documents to request from the defendant.

Research the Product(s) and Manufacturer(s) Involved

Identify Substantially Similar Vehicles

Identify other makes and models that are “substantially similar” to the subject vehicle (also known as “sisters and clones”). This information will be helpful in a variety of ways. Your search for other instances of injury from the defect in your case should include these substantially similar vehicles. Consumer reports of the alleged defect occurring in a substantially similar vehicle will often put the manufacturer on notice of consumer complaints in the subject vehicle. And in discovery, you should seek access to all documents, testing, and other information for all substantially similar vehicles.

Neptune Engineering compiles an annual list of all vehicle sisters and clones dating back to 1974. The 2014 edition has not been issued yet, but monitor neptuneeng.com for the most current version. An expert can also help determine what vehicles may be “substantially similar,” if not identical.

Check for Recalls, Complaints, Service Bulletins, and Crash Tests

Relatively few defects are ever subject to a recall, and absence of a recall does not indicate the absence of a defect. Nonetheless, it is important to seek out recalls of your product and its model twins. The following resources cover most consumer products encountered. First, the National Highway Traffic Safety Administration (“NHTSA”) has a website where you can access information about vehicle recalls, customer complaints, service bulletins, crash tests, and more. NHTSA offers a service that sends notifications of recalls as they occur. Sign up at http://wwwodi.nhtsa.dot.gov/subscriptions/index.cfm. Information about auto-related recalls is also available at www.recalls.gov.[5]

Second, the Consumer Product Safety Commission (“CPSC”) is charged with investigating and overseeing recalls of consumer products other than automotive products. Visit http://cpsc.gov/en/Recalls to view recalls and perform other research.

Third, the Tire Safety Group maintains a database of tire recalls searchable by DOT code. Visit www.TireSafetyGroup.com or download the Tire Facts smart phone app to search for tire recalls.

Finally, the Insurance Institute for Highway Safety rates vehicle performance in crashes. Crash test videos are available on the IIHS YouTube channel at http://www.youtube.com/user/iihs/videos.

Glean Information from Other Cases and Attorneys

Use list serves and your network of lawyers with experience in this field to find out whether the manufacturer has had similar problems with other vehicles, what the manufacturer, its experts, and its employees have said in other cases, and what the key documents are that have been produced in other litigation. Find out what the manufacturer typically argues in defense of its product and analyze your case with that in mind. Watch out for facts like drugs or substance abuse, the blame that may be laid on the at-fault driver (especially if it is your client), “high-speed” collisions, or failure to use a seatbelt, which can impact how the jury sees your case if these facts are allowed in evidence.

Consider the Costs

Properly litigating a product liability claim can be very expensive. Consider whether a jury verdict is likely to cover the costs and still compensate your client. Also determine whether your firm can fund the expenses up front or whether you will need help.

Pick Defendants Carefully

Counsel must consider the practical, financial, and evidentiary hurdles when pursuing a potential products liability claim. In some cases, there may be half a dozen or more potential defendants ranging from a retail service providers all the way to the company that manufactured the specific part that failed in the product. Although it is traditional advice to name all potentially responsible parties, doing so may be at the detriment of the client in some instances, particularly when dealing with foreign entities.

Product and Sub-Manufacturers

Under O.C.G.A. § 51-1-11, the manufacturer of a product is strictly liable for injuries caused by a defect in a product that existed at the time of manufacture. A product manufacturer may fall into one of three categories:

- The actual manufacturer or designer of the product;

- A manufacturer of a component part which failed and caused injury; and

- An assembler of component parts who then sell the item as a single product under its own trade name.

In most cases, the global product manufacturer should be named as a party. This entity will hold the vast majority of design, manufacturing, and consumer complaint documents. Many large companies may have several entities registered with the secretary of state. Review the company website, secretary of state website, and other online resources carefully to ensure that the proper entity is named, and not a holding company. Other lawyers who have traveled this road before may also be able to offer insight.

Where a component part is sourced from a third party, the component manufacturer may also be named in a products liability suit. Morgan v. Mar-Bel, Inc., 614 F. Supp. 438, 440 (N.D. Ga. 1985); Chicago Hardware & Fixture Co. v. Letterman, 236 Ga. App. 21, 23, 510 S.E.2d 875 (1999). Although the final assembler of the product may be held completely responsible, there are several benefits to naming the component manufacturer. First, where a component is sold for use in numerous vehicles, counsel may receive incomplete information about the scope and timing of consumer complaints for the defective part if information is only obtained from one of the final assemblers. The component manufacturer itself can provide complete information, and may also demonstrate that it is more responsible than the final manufacturer that assembles the component parts. Second, either the product assembler or component manufacturer may produce documents intentionally withheld by the other party, which can expose serious discovery abuse. Finally, the component manufacturer is often the best witness for alternative design information to which the product assembler should be, but claims not to be, privy.

Seller / Entity Putting Product in Stream of Commerce

In some cases, the manufacturer of the product will not maintain a company registered in the United States. When this happens, the product is imported through a holding company or third party who assumes legal responsibility for the product.[6] Numerous federal laws place responsibilities on importers to investigate the product’s design and manufacturing processes.[7] The information is supposed to be gathered proactively before importation. These documents can be very useful, especially because most are in English. Naming the product importer can be a win-win scenario. If the importer followed the appropriate guidelines, counsel will have immediate access to the manufacturer’s design, manufacturing, and testing information, particularly including alternative designs. If the importer did not follow the rules, then the jury will likely hold the importer responsibility for its failure to comply with longstanding federal law.

Service Providers

As vehicle systems become more complex, the days of “self-repair” are becoming less frequent. Instead, consumers rely on a “repair shop” for maintenance and a “400-point inspection” (or similarly marketed checkup) of the vehicle. In such cases, even when there is a strong products liability case, the defense may attempt to put blame on the repair shop for failing to detect the defective product and remove it from service. While this defense is often an attempt to avoid responsibility for a bad design or manufacturing defects, in a number of cases, there may be merit to such a claim because the repair shop’s oversight was, in fact, real, and contributed—along with product defects—to the wreck.

For example, what if the tire was “expired” and should have been removed from service? The U.S. Department of Transportation Tire Code (“DOT Code”) printed on every single tire produced since 2000 indicates the week and year that a tire was manufactured.[8] Most automakers recommend such tires be taken out of service—regardless of their tread depth—at the six-year mark, and even the tire industry acknowledges that a tire that is 10 years or older should be taken out of service regardless of its appearance.[9] In that situation, if the vehicle with that old tire was taken into a “service professional” prior to the wreck and the repair shop failed to note or warn of the age of the tire and the potential for failure of an aged tire, you may well have a viable claim against the repair shop, in addition to, a products claim for failure to warn of the dangers of an aged or expired tire.

Conclusion

This article cannot address every nuance of tire and vehicle defect claims but hopefully it will serve as guidance in future case evaluation by helping you explore all potential causes of a tragic event and identify all responsible parties. Pursuing these cases not only helps your client but also the greater good, by making the roadways safer for everyone.

NOTE: This article was originally published in 2013 through the Institute of Continuing Legal Education in Georgia at the Expertise in Plaintiff Personal Injury Law: Learning the Details of Key Practice Areas seminar.

[1] Sinclair, Upton, The Jungle, Ch. 14, Barnes and Noble Classics (2005).

[2] NHTSA, 2012 Motor Vehicle Crashes: Overview, DOT HS 811 856 (November 2013).

[3] In cases where the car was manufactured more than 10 years ago, some of the plaintiffs’ claims will likely be subject to a statute of repose defense. But duty to warn claims are often not subject to that defense, because under Georgia law the manufacturer has an ongoing duty to warn of defects it knows about. In addition, the statute of repose defense is not available where the manufacturer exhibis a “willful, reckless, or wonton disregard for life or property.” O.C.G.A. § 51-1-11(c).

[4] Brennan, Niamh, Accounting Expertise in Litigation and Dispute Resolution, Journal of Forensic Accounting, VI (2): 13-35 (2005); Hannaford-Agor, Estimating the Cost of Civil Litigation, National Center for State Courts, Volume 20 (January 2013).

[5] This central website contains recall information for the Coast Guard, the Consumer Product Safety Commission, the Environmental Protection Agency, the Food & Drug Administration, and the Department of Agriculture.

[6] See 15 U.S.C. §§ 2051–2089, §2052(11).

[7] See Recommended Best Practices for Importers of Motor Vehicles and Motor Vehicle Equipment at http://www.nhtsa.gov/Laws+&+Regulations/ci.Recommended+Best+Practices+for+Importers+of+Motor+Vehicles+and+Motor+Vehicle+Equipment.print (last accessed January 3, 2014).

[8] The last four digits of the DOT Code reveal the week and year in which it was made. For example, if the last four digits are 3006, it means the tire was made in the 30th week of 2006, and is more than six years old as of this conference.

[9] BMW, Ford, Porsche, Toyota, Audi, and GM state that tire more than six years old should be removed from service. N.H.T.S.A., Research Report to Congress on Tire Aging (Aug. 2007). Bridgestone/Firestone, Continental, and Michelin each offer a rambling, largely incoherent warning that ultimately concludes that tires should be removed from service after ten years. See id.